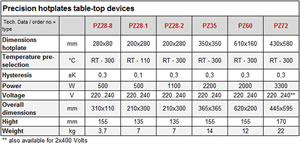

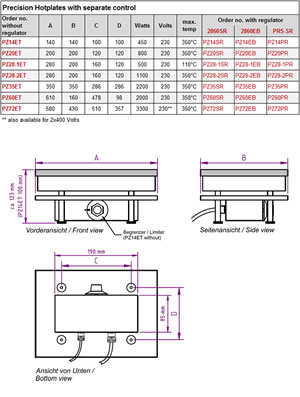

Präzitherm® - Precision hotplates

Construction

The heating surface of the precision hotplates are composed of an efficient heat conducting Aluminium alloy. The surface is smooth, easy to clean, and anodized. The built-in electric long-term heating is designed to provide a very homogeneous temperature distribution even at the corners and edges.

The microprocessor controlled digital regulator allows the operating temperature to be preset in 0.1°C stages up to 99,9°C and in 1.0°C stages for temperatures over 100°C. The set target temperature is retained even after the unit is switched off. Presetting is only possible by using two fingers; this is to prevent any unintentional alterations that could occur by accidentally touching only one key. After releasing the keys, the actual temperature is constantly displayed by 14 mm high digits.

All models have an electronic output control that allows the heating output to be adjusted between 10..100%, this pre- vents the hotplate exceeding the preset temperature and/or avoids any after-heating. The temperature of all hotplates is measured with a built-in, quick-reaction sensor (PT 100).

All types are equipped with a 6-pole extra-low voltage socket to which can be connected, for example a contact thermometer or a timer - to heat and cool the device in intervals; and, temperature fuses for reliable overtemperature protection. Temperature fuses are available in different tripping ranges

Special feature of the precision hotplates:

Due to the asymmetrical, quick-reaction special heating and thermal sensors as well as output adaptation to the thermal requirements, very precise temperatures with a good uniform heat are obtainable over the whole heating surface.

All types are also available with black anodized or teflon-coated heating surface (max. temperature: 260°C) on request.

To ensure the connection to your digital company network and the integration into various automation processes, we are also happy to equip your precision hotplates with various interfaces (e.g., RS485 or RS232).

+49-203-746346

+49-203-746346 +49-203-746637

+49-203-746637

Location

Location